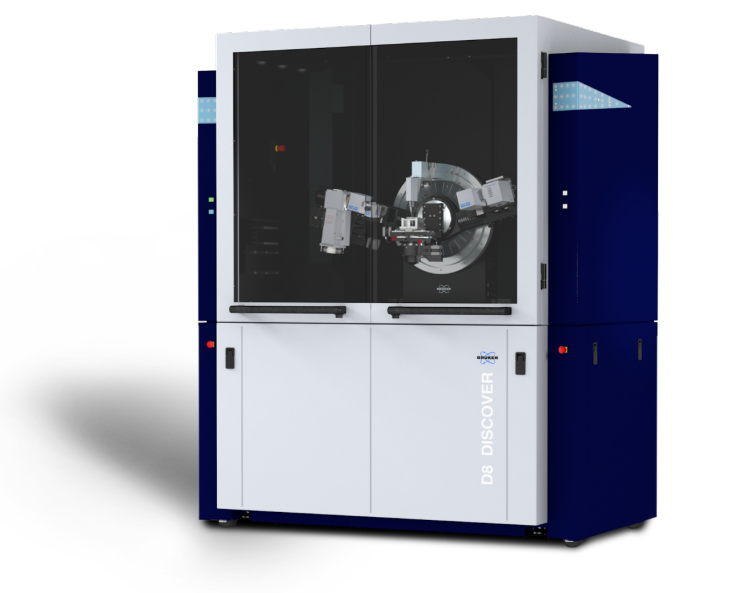

The D8 DISCOVER is a multi-purpose X-ray diffractometer offering leading technology components. In its core is the high-accuracy ATLAS goniometer that hosts the high-efficiency Turbo X-ray source (TXS-HE) and the market-leading Non-Coplanar Arm. It is designed for the structural characterization of the full range of materials from powders, amorphous and polycrystalline materials to epitaxial multi-layered thin films at ambient and non-ambient conditions.

When publishing work with data collected from the Bruker D8 Discover, please use the following phrase for acknowledgment:

"This work made use of University of Utah shared facilities of the Micron Technology Foundation Inc. Microscopy Suite sponsored by the John and Marcia Price College of Engineering, Health Sciences Center, Office of the Vice President for Research. Acquisition of the Bruker D8 Discover system was made possible by the Air Force Office of Scientific Research under project number FA9550-21-1-0293."

General Use and Applications

- Phase identification and quantification, structure determination and refinement, micro-strain and crystallite size analysis.

- X-Ray reflectometry, Grazing Incidence Diffraction (GID), In-Plane Diffraction, High-resolution XRD, GISAXS, GI-Stress analysis, crystal orientation analysis.

- Residual stress analysis, texture and pole figures.

- Total scattering analysis: Bragg Diffraction, Pair-Distribution Function (PDF)

Capabilities

- Rocking Curves. This is a method for analyzing epitaxial structures for which the layer and substrate are almost perfect single crystals. These means the difference in diffraction angle for the layer and substrate is very small and requires the capability to resolve Bragg peaks on an arc second scale. The data is recorded as a rocking curve and can be modeled and fitted to reveal structural details of the epitaxial layer.

- Reciprocal Space Maps. This is a technique for analyzing epitaxial (and similar) thin films. Narrow scans of reciprocal lattice points are performed for various diffractometer settings and the scattered intensity can be plotted in a 2-dimensional frame.

- Texture (pole figures). A pole figure is measured at a fixed scattering angle (constant d spacing) and consists of a series of Phi-scans (in- plane rotation around the center of the sample) at different tilt or Chi angles and measures preferred crystallite orientation.

- Residual stress. Stress is determined by recording the angular shift of a given Bragg reflection as a function of sample tilt (psi). This actually provides a measure of strain in the sample from which the stress can then be calculated by plotting the change in d-spacing against sin2psi.

- Grazing Incidence XRD (GIXD). Enhance diffracted signal from polycrystalline thin films and examine structural variations as a function of depth by precisely controlling incident angle and therefore the penetration depth of x-rays.

- Grazing Incidence In-Plane XRD (GIIXD). In-plane diffraction is a technique for measuring the crystal planes that are oriented perpendicular to the surface. In-plane lattice parameters and crystal orientation can be determined.

- X-Ray Reflectivity (XRR). Measures film thickness, roughness (interface and surface), and density of films (2 nm – 500 nm). Also measures multilayer interface quality and periodicity structure evaluation.

- High-temperature, orientation sensitive XRD. Temperature-induced phase transition investigations, texture measurements, stress, profile analysis, powder diffraction, grazing incidence, and high resolution studies. Powders can’t be analyzed at high temperatures.

Specific Hardware and Software Components

- Eiger R 250k detector. OD, 1D and 2D measurements in step, continuous and snapshot modes.Large area, 38.4 x 38.4 mm Pixel size 75 x 75 micron

- Compact cradle plus. Sample positioning: motorized Chi(tilt) and Phi(rotation) rotations and Z translations, manual X Y stage. The cradle accommodates powders, thin-films, and wafers up to 70 mm in diameter and 25 mm in height, weighing up to 250 g.

- Domed hot stage. Heating device with an x-ray transparent dome designed for orientation sensitive temperature studies from room temperature to 1100 °C in air, vacuum, or inert gas atmosphere.

- Laser/video Sample alignment System. Computer controlled video camera and laser pointer for easy and accurate sample positioning and system alignment.

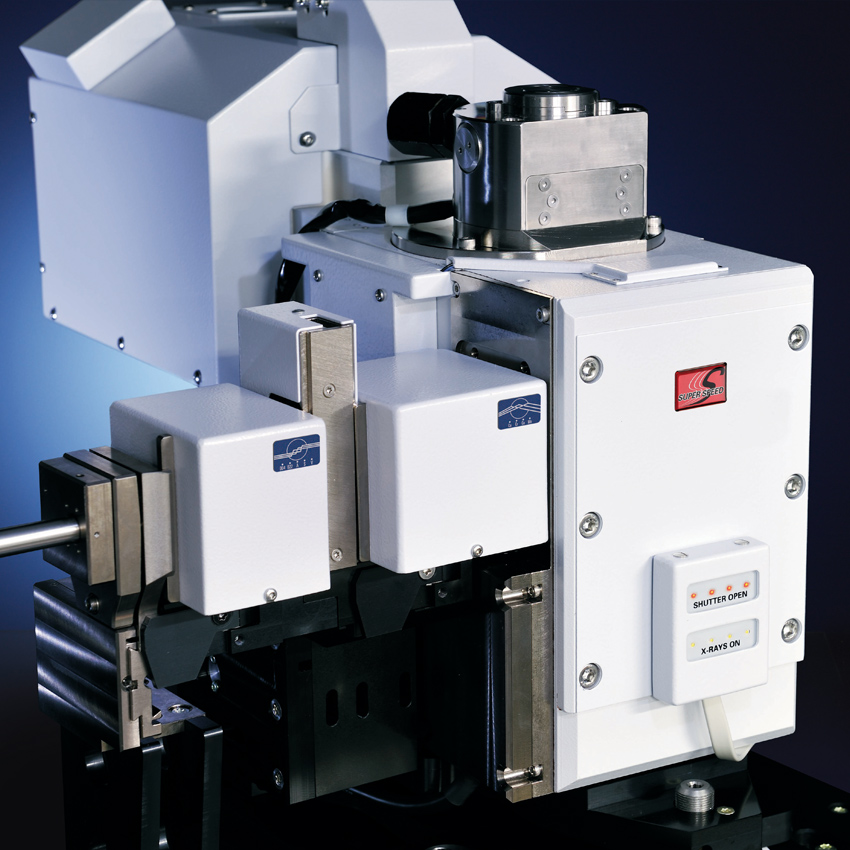

- Pathfinder Plus with 2 bounce Ge(022), automated single-position absorber and motorized slit. Fully controlled multi beampath optics. High intensity beampath with motorized slits for applications like XRR or HRXRD.

- Trio Optic. Fully software controlled mutli beam path optics. Motorized divergence slit for Bragg-Bentano measurements. Gobel mirror for high intensity parallel beam applications like XRR and GID.

- Dual Beam Path analyzer module. Motorized module that allows software controlled switching between 2 diffracted-beam configurations. The first is a high intensity path incorporating a motorized slit, and the second is a high-resolution path incorporating a triple-bounce channel-cut monochromator.

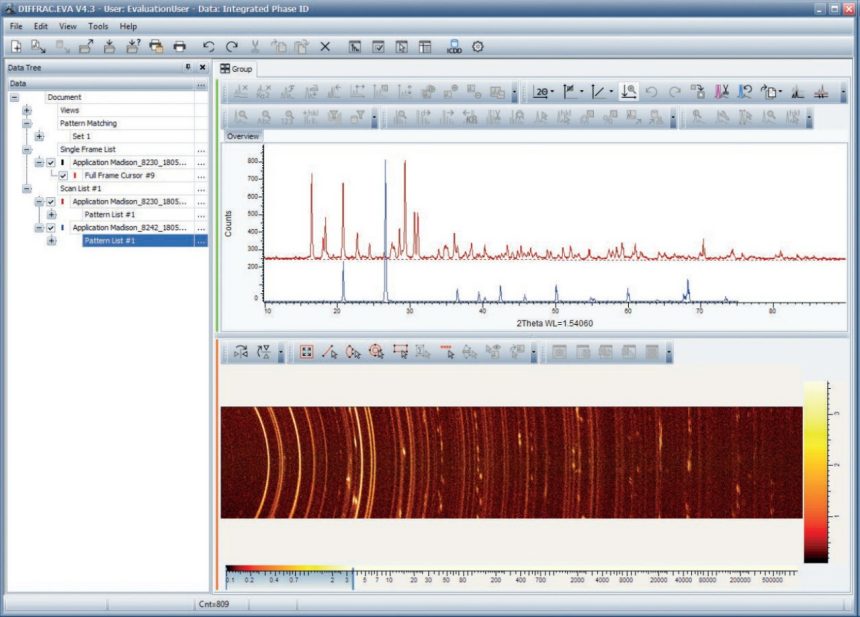

- DIFFRAC Measurement center. Software package for easy and convenient 1 and 2 D xray scattering and diffraction data.

- DIFFRAC EVA. Analysis package for phase ID with integrated quantitative analysis. Cluster analysis is providedto match and analyze powder diffraction patterns.

- DIFFRAC Texture. Texture analysis using both the Harmonics and Component methods.

- DIFFRAC Leptos. Thin film, stress and nanoparticle analysis software package.

| HOURLY RATES | ||

| Users | Daytime | Overnight M-F: 5pm - 8am Sat-Sun: All Day |

| On-Campus members | $ 35.00 | $ 17.50 |

| Off-Campus Academic | $ 53.90 | $ 26.95 |

| Industry | $ 70.00 | $ 35.00 |

| CONTACT US FOR MORE INFORMATION: | |

| Dr. Bobby Duersch | Lab: 801-587-3108 Office: 801-587-0684 |