X-RAY, AUGER, ULTRAVIOLET PHOTOELECTRON SPECTROSCOPY (XPS),(AES),(UPS): KRATOS AXIS ULTRA

- Quantitative chemical analysis of the top 10 nm surface layer

- Identification of bonding and oxidation state of elements on the surface

- Overlayer thickness measurement up to ~10 nm

- Depth profiling of up to ~100 nm using Ar+ ion sputtering

- Fermi-level and work function measurement via ultraviolet photoelectron spectroscopy (UPS) with He(I) and He(II) sources

- Scanning electron and scanning auger microscopy ~15 μm resolution

- Chemical analysis of the top monolayer using ion scattering spectroscopy (ISS) with He ion source

ATOMIC FORCE MICROSCOPY (AFM): Bruker Icon

- High-resolution imaging and measurement of surface height features at angstrom scales

- Quantitative measurement of sub-nanometer scale surface roughness

- Easy instrument operation with the use of Bruker ScanAsyst™ and PeakForce™ tapping modes

- Contact and tapping imaging modes

- Magnetic force microscopy

- Fluid cell imaging for biological samples

- Special deep trench probe for high aspect ratio surface features

NANOINDENTER: Bruker Hysitron TI Premier

- Measurement of material hardness, Young’s modulus, fracture toughness and other mechanical properties

- Analysis of semiconductors, polymers, metals, thin films, and multiple layers

- Identication of topographical features

- Acquire additional information about the deformation in post-scanning, and measure quantitative RMS surface roughness

- Maximum applicable load ~100 μN

- Nanoscale mechanical and tribological behavior of materials at elevated temperatures up to 800°C

- Optional inert gas flow over sample to prevent material oxidation at elevated temperature

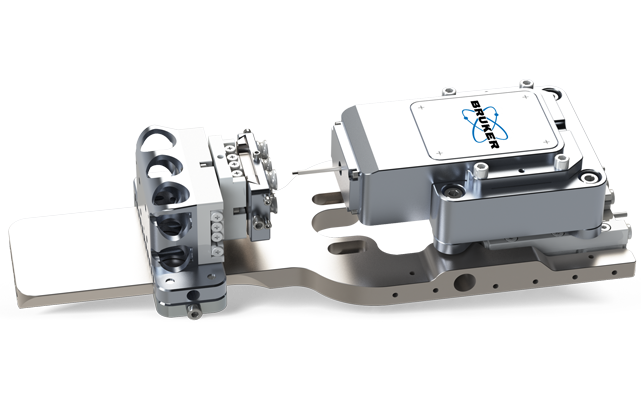

PICOINDENTER: Bruker Hysitron PI89

- Used for nanoindentation, tensile testing, pillar compression, cantilever bending, fracture, fatigue, dynamic testing, mechanical properties mapping

- Intrinsic displacement actuation and displacement control from <1nm to 150µm

- Load range from <1µN to 3.5N, and 78kHz

- 1 nm encoded linear stages provide greater repeatability during automated testing modes while increasing travel range

- The uniquely low-current design of the transducer minimizes thermal drift and provides unprecedented load and displacement sensitivity

OLYMPUS LEXT OLS5000

- Non-contact, 3D, surface metrology at~10 nm resolution (z)

- Wide range of objectives: 5x, 10x, 20x (SLWD),50x (LWD), 100x

- Surface roughness, surface area, line profile,film thickness, step height measurements and more

- Automated report generation feature

- True, quantitative 3D imaging

- High aspect ratio structure measurements:measure surface features at up to 87° with respect to the light source

- Two imaging modes: 3D image + true color optical microscope image

WOOLLAM VARIABLE ANGLE SPECTROSCOPIC ELLIPSOMETER (VASE)

- Measurement of thickness of transparent thin films (i.e., optical coatings, photosensitive coatings

- Measurement of index of refraction and extinction coefficient

- Applicable to thin film thickness ranging from 1 monolayer to >1 micrometer

- Useful for single layer, and multilayer components

- Light source wavelength range: 190 – 2000 nm

- Xe Arc lamp and monochromator

- Angles: 70 – 75° for typical measurement

- Designed for planar samples

- Can hold wafers up to 4”

- Automated multi-spot data collection