The X-ray Microscope provides non-destructive, 3D imaging of materials at up to 600 nm resolution

General Use and Application

-

- Crystallographic imaging modalities enabled by lab DCT

- Characterize material evolution over time (heat, cool, mechanical load)

- In-situ heating/cooling/tension/compression stage. Up to 5kN loads to materials.

- Large volume sample imaging enabled by Flat Panel Extension

- Tomographic Reconstruction software

- 3D visualization and segmentation software (Dragonfly Pro)

Click here to see the Nano-CT in operation!

For more information please contact:

Dr. Brian Van Devener (801-585-6162; b.van-devener@utah.edu)

Imaging Capabilities

- Deben CT5000-TEC 5kN in situ load/tensile stage. Cooling/heating from -20 C to +160 C

- High spatial resolution (600 nm)

- High resolution imaging at large working distances (RaaD)

- Flat panel extension (FPX) enables large volume imaging for large samples

- Versatile sample types and sizes. Stage travel range: x – 50 mm, y – 100 mm, z – 50 mm

- Lab DCT enables crystallographic imaging modalities

- DragonFly Pro Software for 3D imaging and reconstruction

- Wide Field imaging mode: 0.4x, 4x

- High resolution 40x detector kit

- 160kV, 25W microfocus xray source

| HOURLY RATES | ||

| Users | Daytime | Overnight M-F: 5pm - 8am Sat-Sun: All Day |

| On-Campus members | $60.00 | $30.00 |

| Off-Campus Academic | $92.40 | $46.20 |

| Industry | $120.00 | $60.00 |

| CONTACT US FOR RESERVATIONS: | |

| Dr. Randy Polson | Lab: 801-587-3108 Office: 801-587-0873 |

Specific Use and Application

Microscopy Solutions for Materials Science

- Characterize three-dimensional structure

- Observe failure mechanisms, degradation phenomena, and internal defects

- Investigate properties at multiple length scales

- Quantify microstructural evolution

- Perform in situ and 4D (time dependent) studies to understand the impact of heating, cooling, desiccation, wetting, tension, compression, imbibition, drainage and other simulated environmental studies

- Understand the 3D structure of fibers as well as pores and pore pathways in paper

- Observe the propagation of a crack inside your sample

Electronics and Semiconductors

- Perform structural and failure analysis for process development, yield improvement and construction analysis of advanced semiconductor packages, including 2.5/3D and fan-out packages

- Analyze printed circuit boards for reverse engineering and hardware security

- Non-destructively image across length scales from module to package to interconnect for submicron-resolution characterization of defects at speeds that can complement physical cross-sectioning

- Enable better understanding of defect locations and distributions by viewing unlimited virtual cross-section and plan-view images from all desired angles

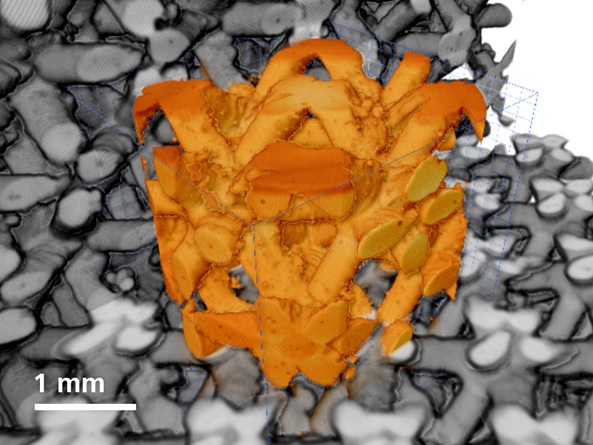

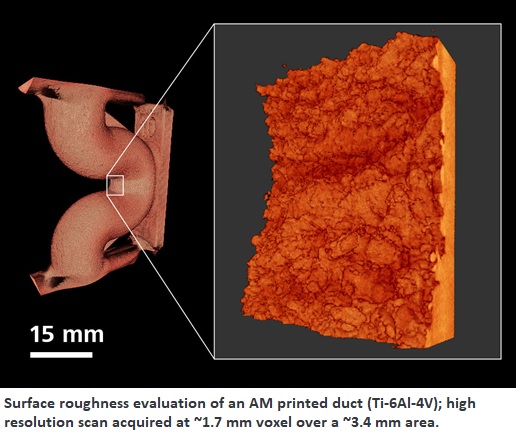

Microscopy Solutions for Additive Manufacturing

- Detailed shape, size, and volume distribution analysis of particles in Additive Manufacturing (AM) powder bed to determine proper process parameters

- High-resolution, non-destructive imaging for microstructural analysis of AM parts

- 3D imaging for comparison with the nominal CAD representation

- Detection of unmelted particles, high-Z inclusions, and voids

- Surface roughness analysis of inner structures that cannot be accessed by other methods

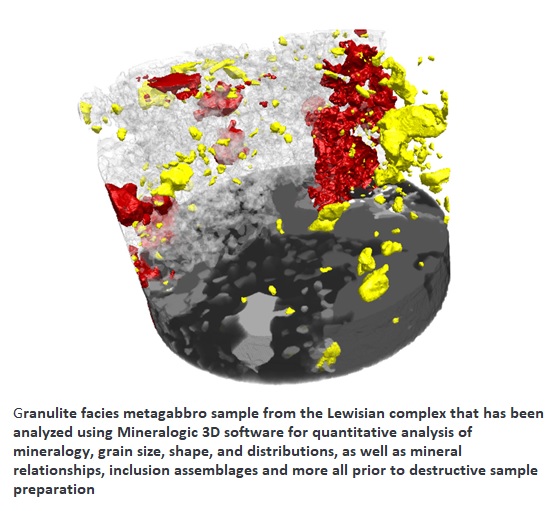

Microscopy Solutions for Raw Materials

- Achieve automated mineralogy in 3D with little to no sample prep

- Perform multiscale pore structure and fluid flow analysis, directly measure fluid flow using in situ flow equipment

- Perform non-destructive scout scans and cut to ROI for buried structures in metamorphic rocks

- Analyze grain orientations in steel and other metals